by Jere Dennison

In September 2002, this column briefly covered the history of the original Stingray Point Lighthouse constructed in 1858 and its subsequent demolition in 1965. Also mentioned was the in-process effort by Stingray Point Marina to construct a faithful replica of the original lighthouse at the marina site. Stingray Point Marina has kindly provided us with construction details of the new screwpile lighthouse completed in March 2003 and, with the owner's permission, we are reprinting those details below for those members who may be interested in the architectural and engineering aspects of this ambitious and successful project to recreate an area icon.

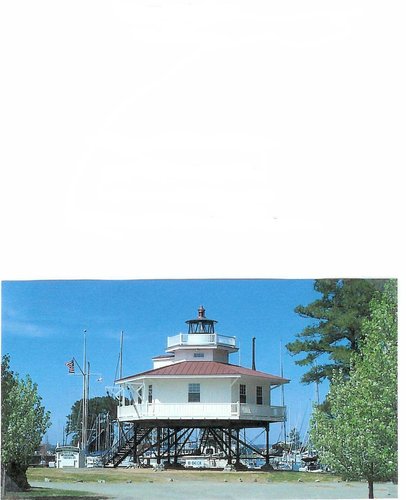

The Stingray Point Replica Lighthouse (Picture and Text Courtesy Stingray Point Marina)

The new Stingray Point Lighthouse Replica, located on land next to the water on the premises of the Stingray Point Marina, was completed in March 2003. It is approximately 1.6 miles due west from the original lighthouse site. The US Lighthouse Establishment created measured drawings of Stingray Light in 1884, which are, located in the Philadelphia National Archives. A copy of the elevation drawing from the original 1858 drawings was also obtained. The remaining base steel structure now supporting the automatic light was measured to confirm consistency with the drawings. In 1885, Major Jared Smith photographed Stingray Point Light among a number of lighthouses for the Lighthouse Establishment. The Mariners Museum holds the negative to this photograph.

From these documents, Randall Kipp, an Irvington, Va. architect, developed working drawings for the new lighthouse, rigorously adhering to the structure and dimensions of the original. Northwind, Inc., of Deltaville, Arthur Wilton, owner, contracted for the construction of the project. Atlantic Metals of Topping, Va. fabricated and erected the base steelwork. Charles Yeager Designers & Fabricators designed the base steelwork and designed and fabricated the aluminum and copper portions of the lantern room.

A number of artifacts have been collected, none original to Stingray, but dating to the late nineteenth century and similar to equipment used at Stingray. Most of these were acquired through the auspices of Kendrick A. Claflin & Son, a nautical antique dealer in Worcester, Mass. These include a fifth order, drum type Fresnel lens. Lens orders ran from one, the largest, to seven, the smallest. The Fresnell lens consists of a central magnifying "bull's eye" lens, above and below which are a series of prisms which receive and bend the light not transmitted through the bull's eye into a path parallel to the central beam, thus dramatically increasing the visibility of the light emanating from a relatively small source. Drum lenses (cylindrical in shape with no beehive shaped top or bottom) were American produced and much less expensive than the French made beehive lenses. They were installed in a number of lighthouses and large buoys in the early 1900s including Thimble Shoals Light at the Hampton Roads entrance and many of the lighthouses in Nova Scotia. The acquired Stingray lens was manufactured by the American Gas Accumulator Company of Elizabeth, NJ, probably early in the twentieth century, and could have come from a large buoy, if not a lighthouse. This Company was originally derived from the Swedish Acetylene Gas Accumulator Company (AGA), founded by Gustav Dalen, who received the Nobel Prize for his invention in mid Nineteenth Century of a device which, by means of the suns heat, turned acetylene lamps in lighthouses on and off. Dalen also developed the famous AGA stove. The French made, beehive type, Fresnel lenses are largely located in museums or restored lighthouses, not generally available, and considered works of art. The Mariners Museum has six of these lenses, including first, third, fourth, and fifth order lenses and the Coast Guard Station at Yorktown has several examples of each order. The Stingray Replica lens is routinely lit by a 26 watt fluorescent bulb but is configured so that it can be lit by a kerosene lamp.

Also acquired was a 1942 Coast Guard bronze fog bell. This bell was originally used on a bell buoy. It weighs 300 lbs. and has a 20" rim. The original Stingray bell had a 30" rim and weighed an estimated 1000 lbs. To strike the bell, a circa 1880 bell striking machine has been acquired, manufactured by the Gamewell Company, which supplied many such machines both to lighthouses and to fire stations during this period. The machine operates on the principle of Jefferson's weight driven clock, with weights extending through the floor to provide the energy for the hammer to hit the bell. A mechanical clock timer activated the earliest machines while later machines were triggered by a 6-volt electro-magnetic solenoid, also activated by a mechanical clock. During periods of fog, the bell would be rung every ten seconds. The lighthouse keeper had to rewind the weights at intervals, typically after five to six hundred strokes (two to three hours). The Gamewell machine at the Lighthouse Replica has an electro-magnetic solenoid and was originally located in a fire station.

Because of functional requirements, the interior main floor layout of the replica differs from that of the original. The original layout consisted of a living room, a bedroom, and a kitchen. It also included a rather large coal bin. The layout of the replica substitutes an office for the bedroom and the kitchen is open to the living room. The living room is used to display lighthouse drawings, marine art, boat models and lighthouse artifacts as they may be acquired. The second level Watch Room and dormer, and the third level Lantern Room are unchanged from the original.

The Stingray Point Lighthouse Replica has numerous unique construction features, displaying the superior skills of the Northwind carpenters. The cottage support platform is under-girded with six hexagonally configured steel beams, with seven 3"x12", old, heart pine beams between each of the six steel beams. Each of the wooden beams terminates in a mortise & tenon connection to a ribbon facia board. Directly on top of these beams is a sub-floor of hexagonally configured 1"x 6" Brazilian hardwood. An insulation layer is followed by a sealed plywood layer, on top of which is a finished, beveled edge, Brazilian hardwood floor, again hexagonally configured with screwed and plugged fastenings, and varnished with tongue oil sealer.

A 10" diameter pine pole extends from the center of the main floor to the base of the lantern room, around which is constructed a wooden spiral staircase. The staircase has Brazilian hardwood treads and beaded tongue and groove risers. A trapdoor at the foot of the stairs provides access from underneath the cottage by means of a steel ladder and ramp. The ramp extends to the edge of the lighthouse to a point under a pair of davits for lifting the keeper's boat. Trap doors in the ceiling of the watch room provide access to the lantern room and to the widows walk.

The interior walls of the lighthouse are 5 inch, beveled, tongue and groove pine. The external walls are cedar, board and batten construction. All wall framing is 2"x 6" salt treated pine. The exterior decking is 2" cypress. The lantern room circular base is constructed of 4 inch tongue and groove pine and the beacon enclosure is aluminum with 12 trapezoidal, glass, thermo-panes and topped by a copper ventilator and copper roof with a lightning rod spire. The Fresnel lens is mounted on a 45" high, stainless steel pedestal. The main roof is painted tin, using hand crimped standing seam construction, The living room is equipped with a wood burning, potbellied stove connected to a tall stack with an L shaped rotating wind vane rain protector. The lighthouse is fully heated and air-conditioned.

It is intended that the Stingray Point Lighthouse Replica serve not only as a strong identifying symbol for the Stingray Point Marina, but also as a Deltaville icon, celebrating the seafaring traditions of the community. The lighthouse is open to the public when the Marina office is open and by appointment.